Keep Komfort

Keep Komfort

For facilities with distributed local thermostats or legacy BMS that are in need of reducing energy usage while improving comfort.

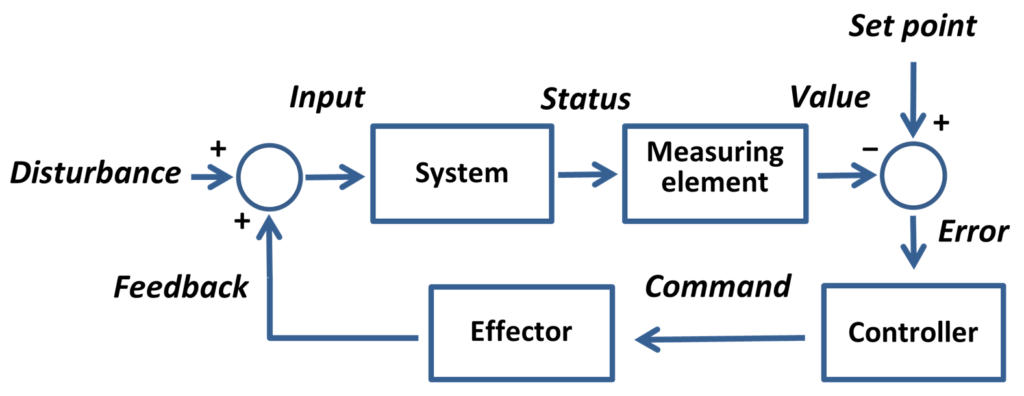

Communicating thermostats are deployed that coordinate with the SEAP platform, local microprocessors, the RTU, and additional intelligent sensing to drive out costs, while improving comfort.

Roof Top Unit Performance

Keep Komfort reduces energy costs both at the local RTU system level and at the facility level, while improving resiliency by intelligently focusing on when to use energy and commanding this usage in coordination with the facility, onsite generation & storage, and the utility’s tariffs.

Customers typically reduce their cooling costs by 20% while improving comfort for customer satisfaction and productivity.

Energy Asset Monetization

Keep Komfort is installed as a direct replacement of the RTU's temperature controller devices and additional sensors. Through Keep Komfort’s integration with the our EMIS-ASO module, commanded temperature modulation enables the facility spaces to be utilized as energy storage to support facility resiliency, energy efficiency, peak load management, microgrid supply/load balancing, and participation in utility demand response programs. Locally installed micro-processors & intelligent thermostats coordinate with the SEAP cloud servers, local microgrid controllers, and your existing RTU to secure un-interrupted efficient and reliable operations.